- My Forums

- Tiger Rant

- LSU Recruiting

- SEC Rant

- Saints Talk

- Pelicans Talk

- More Sports Board

- Fantasy Sports

- Golf Board

- Soccer Board

- O-T Lounge

- Tech Board

- Home/Garden Board

- Outdoor Board

- Health/Fitness Board

- Movie/TV Board

- Book Board

- Music Board

- Political Talk

- Money Talk

- Fark Board

- Gaming Board

- Travel Board

- Food/Drink Board

- Ticket Exchange

- TD Help Board

Customize My Forums- View All Forums

- Show Left Links

- Topic Sort Options

- Trending Topics

- Recent Topics

- Active Topics

Started By

Message

Are non-brushless power tools not as good as brushless power tools?

Posted on 3/13/20 at 11:45 am

Posted on 3/13/20 at 11:45 am

Looking to get a cordless drill and cordless impact combo. The brushless options are more expensive and sometimes sold out compared to non-brushless. What am I missing here?

Posted on 3/13/20 at 11:51 am to finchmeister08

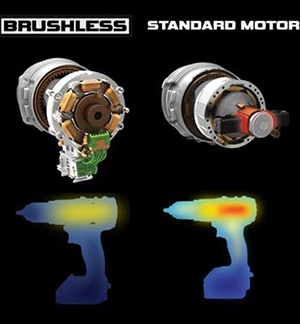

No, they're not, but it's a question of degree. Brushless tools have less friction, less heat, longer run time. It's not something you'd notice for short home tasks, but if you're building a deck it's worth the upgrade.

Posted on 3/13/20 at 11:51 am to finchmeister08

quote:

What am I missing here?

Brushless drills are better in almost every way. Except price. They run cooler, less friction so less wear, more torque and faster speeds.

Posted on 3/13/20 at 12:19 pm to highcotton2

Pro use get brushless

Home use doesn't matter much

I am not running out and replacing all my non-brushless tools because brushless are now available...

Home use doesn't matter much

I am not running out and replacing all my non-brushless tools because brushless are now available...

Posted on 3/13/20 at 12:20 pm to highcotton2

Learned something today, thanks baws.

Knew "brushless" electric motors of all kinds cost more than non-brushless, now I see why.

The more you know........

Knew "brushless" electric motors of all kinds cost more than non-brushless, now I see why.

The more you know........

Posted on 3/13/20 at 12:21 pm to finchmeister08

Brushed tools are absolutely more durable and can handle situations that pull maximum current draw from the battery better. Those that say there is less heat involved, bullshite. They simply don't know brushless cordless tools operate. They require much more circuitry than brushed tools (also a source of failure) and the high current switching devices generate a LOT of heat. Brushed tools do not require the high frequency power supply switching because they are not converting DC to AC, they simply need PWM and basic feedback to protect the tool. Brushless tools require constant monitoring to operate at all as well as sense when the tool is close to overuse. Brushed tools offer a little bit better control as the current delivered to the motor is more linear while brushless has definite steps in how current is delivered. The tools I use for the heavy jobs are all brushed, they are cheaper to maintain and overall more durable as the failure point is often the brushes that at only a few dollars to replace vs. a potted micro-controller or a Hall-effect sensor which are not only more expensive but a hell of a lot harder to replace. I have a few brushless and they are only for light-duty stuff or where a smaller sized tool is needed. Battery life is a wash, if you are professional user you are going to have charged batteries ready to go and you have probably invested in a few 5, 6, or 9aH batteries anyway. If you are a casual DIYer then you probably don't use the tools enough to really appreciate or benefit from the difference.

Posted on 3/13/20 at 12:54 pm to Clames

quote:

Those that say there is less heat involved, bullshite.

If physics is bullshite, sure.

Posted on 3/13/20 at 1:16 pm to highcotton2

Show an actual thermograph with the heat generated in the tool handle, where there's an aluminum plate acting as a heatsink in better tool brands. If you can't find one let me know, I own a high-resolution FLIR thermal camera and can show you the 257F temperature of the control block in handle of the brushless tool. Those carbon brushes get damned hot, more due to the current than friction, but they can handle it much better than the several MOSFETS epoxied into an unserviceable block. They also cost about $8 to replace vs. about $40 for the whole module. Which in a $160 tool is a bit steep but not much choice because you can no longer do component-level repair when everything is cemented together. If you truly believe all the marketing wank then go walk down the power tool aisle at your local Home Depot and look at the tools still using brushed motors. Hole-hogs, circular saws, miter saws, table saws, combination hammers, grinders, sawzalls....all the heavy-duty stuff. You'd think they'd be included in the "more power and durability" claims seeing as those are tools geared more towards professionals. Only Hitachi seems to have made any significant investment in corded AC brushless tools and I don't see any of them stocked at the tool suppliers I use or at any construction sites.

Posted on 3/13/20 at 1:23 pm to finchmeister08

Brushless tools are more reliable because they lack brushes (hence the name). Brushes can wear out over time or sometimes a brush can get stuck in its holder. All this being said if you only use your tools around the house they will last forever

Posted on 3/13/20 at 1:30 pm to Flats

quote:

If physics is bullshite, sure.

Please, when I woke up today and probably forgot more about physics than you have ever learned. Brushless is about profits in an industry that needs to squeeze out every microgram of it to stay competitive. They sell you on the fewer parts involved in brushless tools by telling you it's more durable, when they should be telling you that Chinese micro-controllers are pennies each these days and farming out the driver modules to make power tools cheaper to assemble is the real reason they have people jumping on the bandwagon. It's another cost, and too often a quality, cutting measure. You are not actually getting a better tool, just one that you will have to throw away because the cost/time benefit of repairing it simply isn't there compared to buying a new one.

Posted on 3/13/20 at 1:43 pm to Clames

quote:

Please, when I woke up today and probably forgot more about physics than you have ever learned.

Ok, mensa. If I recall correctly you were also the "my knife choice is the only knife choice" guy in that thread. You're this kid.

Posted on 3/13/20 at 1:56 pm to Flats

quote:

If I recall correctly you were also the "my knife choice is the only knife choice" guy in that thread

Damned good choice, maybe I simply know what's a good value and what isn't. Much like in this thread, take notes kid.

Posted on 3/13/20 at 2:04 pm to finchmeister08

quote:

Looking to get a cordless drill and cordless impact combo.

There are tons of articles that show the advantages of brushless drills. So in conclusion of this thread just buy a brushless drill because it is superior in every measurable metric.

Posted on 3/13/20 at 4:02 pm to finchmeister08

quote:

Looking to get a cordless drill and cordless impact combo.

We use a couple of 1/2” drive Milwaukee impacts on the farm. Pretty crazy how much power you can get out of a battery tool now. It has been a long time since I have used a corded drill. Drilled some 3/4 inch holes about 6” deep in concrete putting in some grain bin anchors and used a 1/2” drive cordless hammer drill. In the past that would have been done with an ac drill for us.

Posted on 3/13/20 at 5:05 pm to finchmeister08

quote:

Looking to get a cordless drill and cordless impact combo.

Makita 18v stop looking lol

Had my set 7 years plus. I purchased the outdoor power stuff maybe a year ago that uses two 18v to make 36v. I'm impressed did a review here on the forum. Spend the $ for the brushless if you can....buy once cry once;)

For what it's worth: The men that suggested I go Makita install garage doors, Florida, tons of self tappers and concrete drilling. They switched from DeWalt to Makita for warranty reasons. DeWalt said abuse the men said it's work.

Posted on 3/13/20 at 8:46 pm to Clames

quote:

Battery life is a wash, if you are professional user you are going to have charged batteries ready to go and you have probably invested in a few 5, 6, or 9aH batteries anyway. If

You don't know what the frick you're talking about

quote:

More energy-efficient.

Because there are no brushes rubbing against anything, no energy is lost due to friction. That means brushless motors are more energy-efficient than brushed drills and can run on batteries for up to 50 percent longer. "That energy efficiency translates into more powerful drills, because there's no mechanical limitations posed by brushes," says John Banta, who oversees CR’s drill test lab.

2. More responsive.

A drill with a brushless motor adjusts its speed, torque, and power supply to match the task at hand. It’ll sense if you’re driving screws into a light material like drywall or a dense material like mahogany, and use only enough power to accomplish the job. (This also contributes to a brushless motor's efficiency by conserving energy stored in the battery.) A brushed motor will use the same amount of power no matter what resistance it’s up against.

3. Capable of packing more power, torque, and speed.

Without brushes to cause friction and slow things down, brushless drills pack more power and torque. They can reach higher speeds, too. "You can expect a 15 to 35 percent increase in performance compared to a brushed motor drill," says Banta.

4. Easier to maintain.

A brushed drill requires new brushes after every 50 to 60 hours of use, but brushless models don’t have any brushes that need replacement.

Do us all a favor and quit posting things you THINK you know.

This post was edited on 3/13/20 at 8:52 pm

Posted on 3/13/20 at 8:58 pm to WHATDOINO

Bought the Kobalt brushless at Lowe’s. Batteries are half the price of Bosch and dewalt.

Posted on 3/13/20 at 9:09 pm to highcotton2

quote:

We use a couple of 1/2” drive Milwaukee impacts on the farm.

Do yourself a favor and get the 3/8” drive Stubby impact from Milwaukee. That thing is amazing. It gets used around our grain bins more than anything else. It’s nice not to have to lug that big 1/2” drive impact around to remove covers or replace paddles and it can get into a lot tighter spaces.

Posted on 3/13/20 at 9:10 pm to finchmeister08

quote:

Bought the Kobalt brushless at Lowe’s. Batteries are half the price of Bosch and dewalt.

It's a good home tool. The dewalts are more for professional use. I use all dewalt and Milwaukee along with makita. They re all close to each other with each having its pros and cons

Popular

Back to top

9

9